|

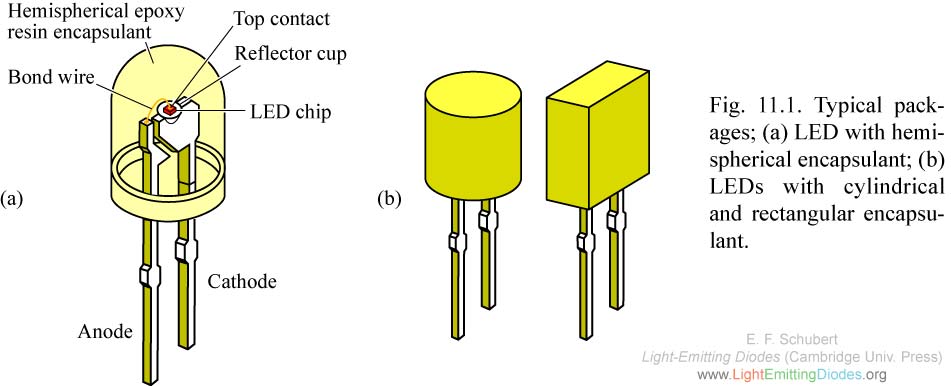

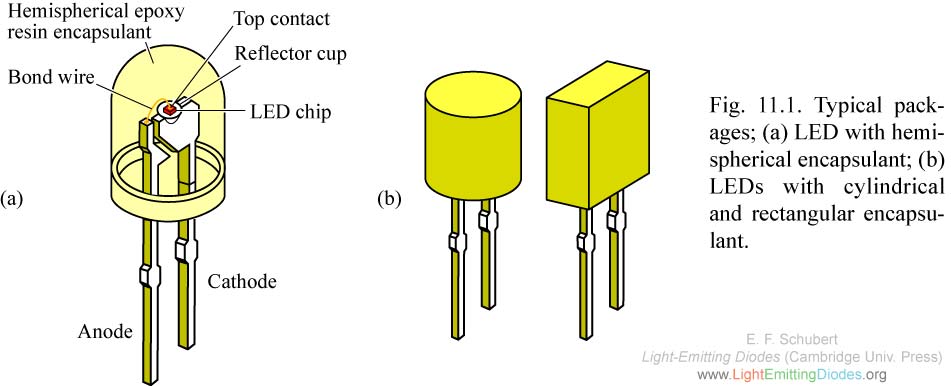

Fig. 11.1. Typical packages; (a) LED with hemi- spherical encapsulant; (b) LEDs with cylindrical and rectangular encapsu- lant.

|

|

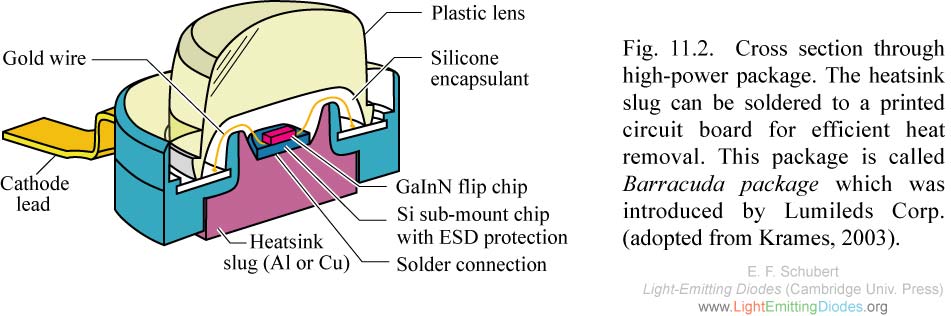

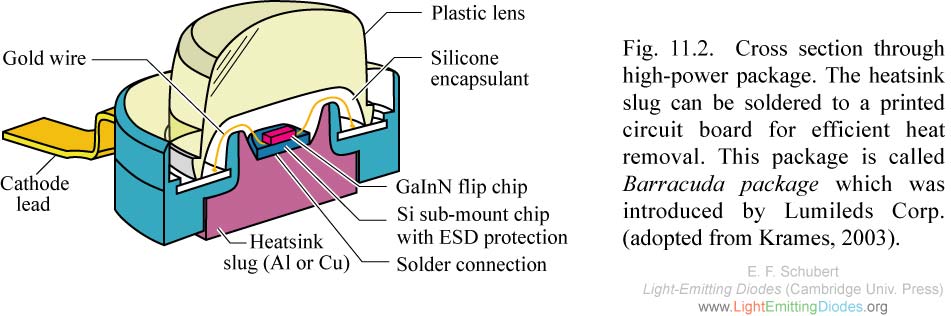

Fig. 11.2. Cross section through high-power package. The heatsink slug can be soldered to a printed circuit board for efficient heat removal. This package is called Barracuda package which was introduced by Lumileds Corp. (adopted from Krames, 2003).

|

|

Fig. 11.3. (a) High-power package; (b) LED die in package; (c) package on printed circuit board with high thermal conductivity. ((a) after Krames, 2003; (b), (c) after after LED Museum, 2003).

|

|

Fig. 11.4. (a) Electrostatic discharge (ESD) protection circuits using multiple pn junctions or Zener diodes. (b) ESD protection incorporated in Si submount.

|

|

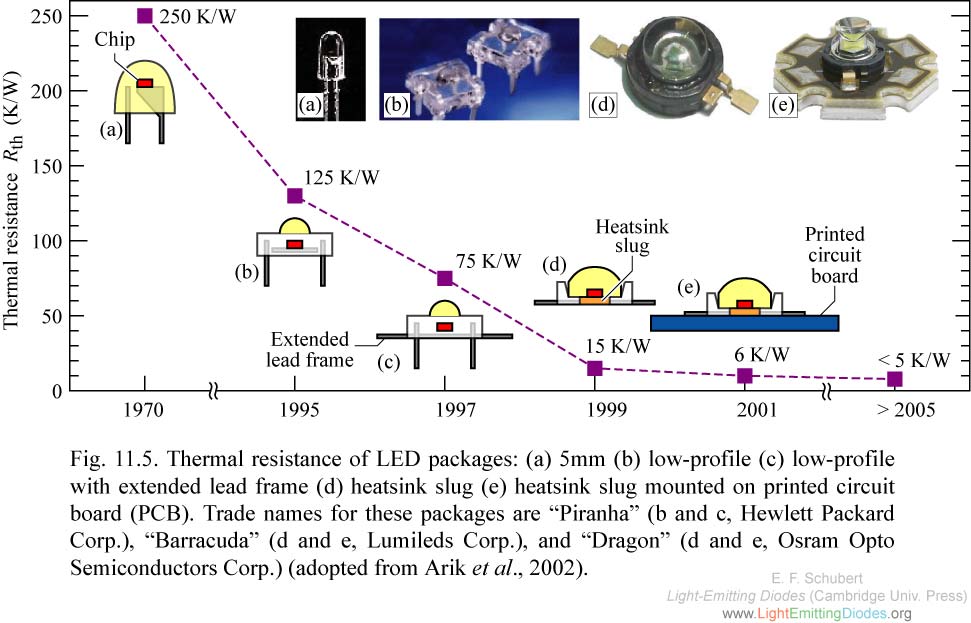

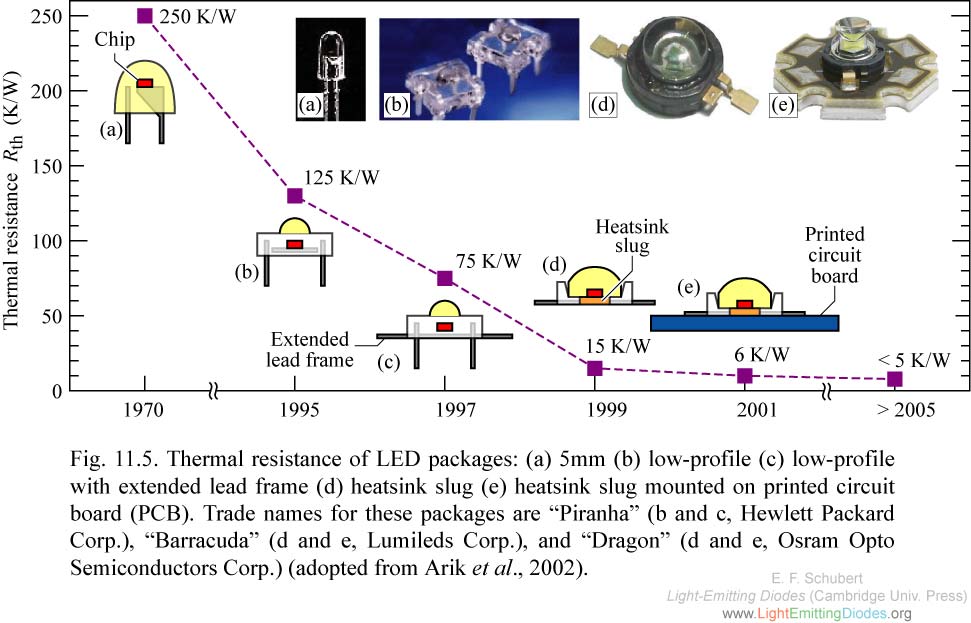

Fig. 11.5. Thermal resistance of LED packages: (a) 5mm (b) low-profile (c) low-profile with extended lead frame (d) heatsink slug (e) heatsink slug mounted on printed circuit board (PCB). (adopted from Arik et al., 2002).

|

|

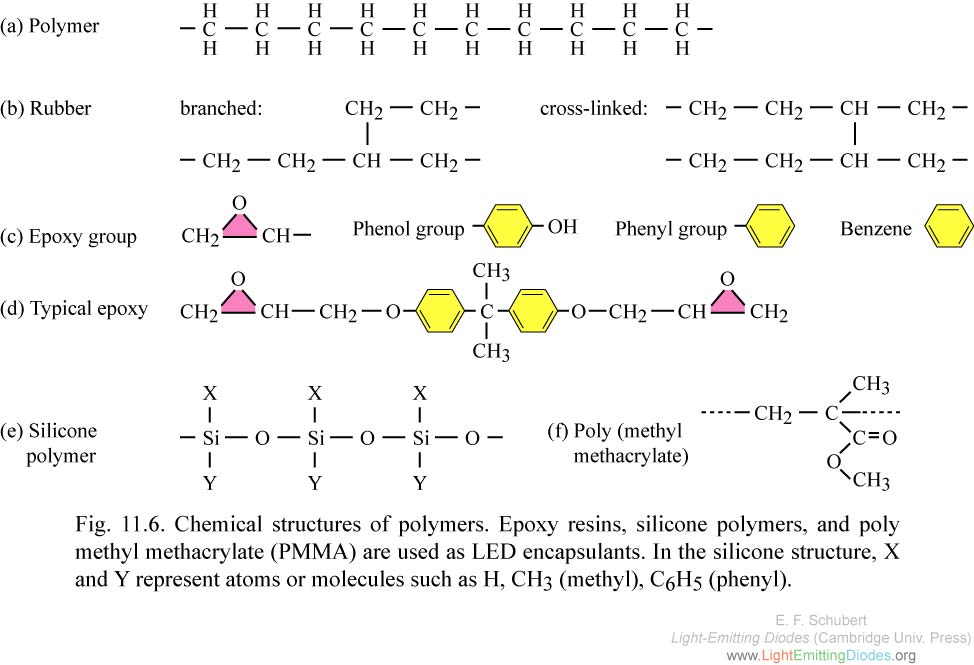

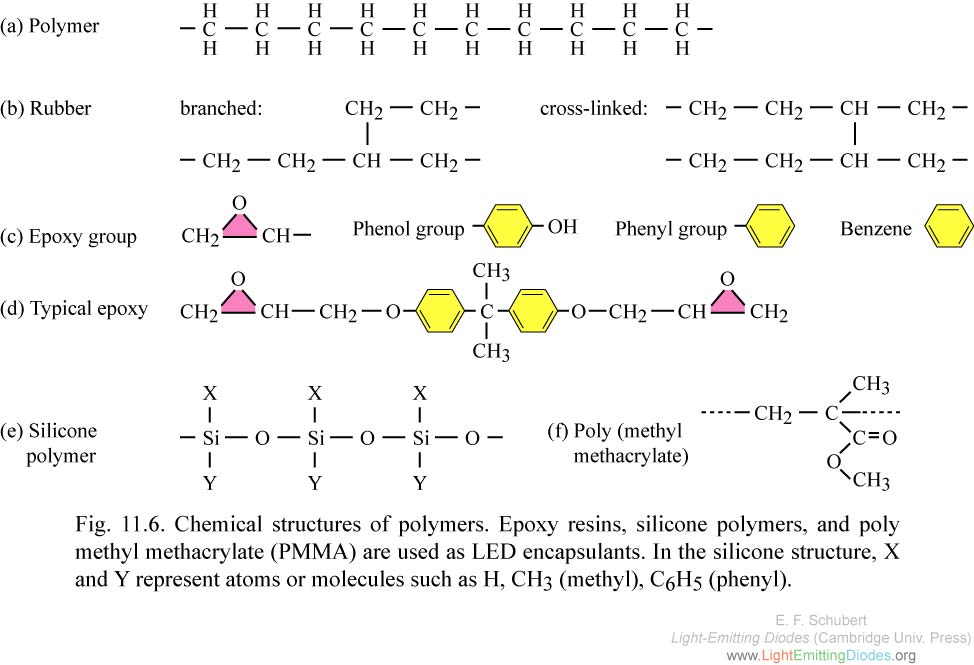

Fig. 11.6. Chemical structures of polymers. Epoxy resins, silicone polymers, and poly methyl methacrylate (PMMA) are used as LED encapsulants. In the silicone structure, X and Y represent atoms or molecules such as H, CH3 (methyl), C6H5 (phenyl).

|